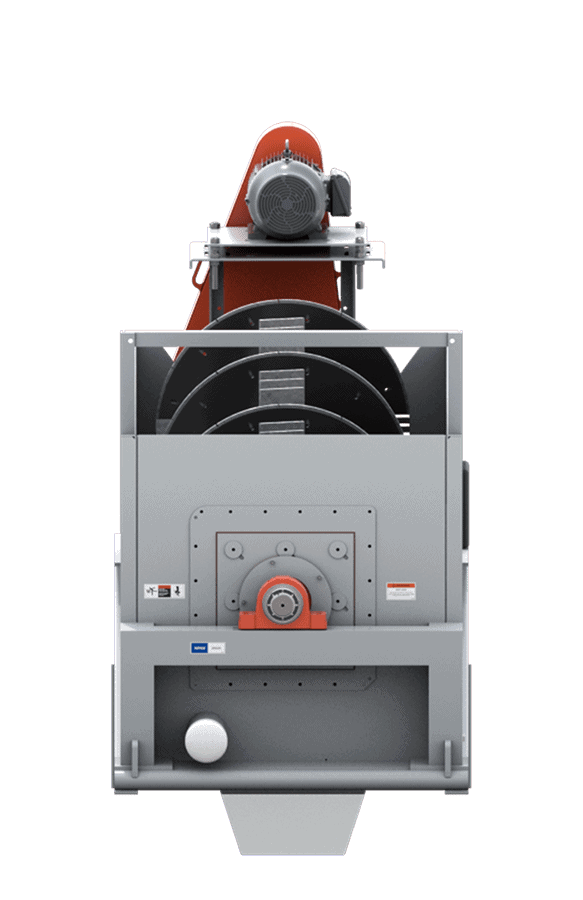

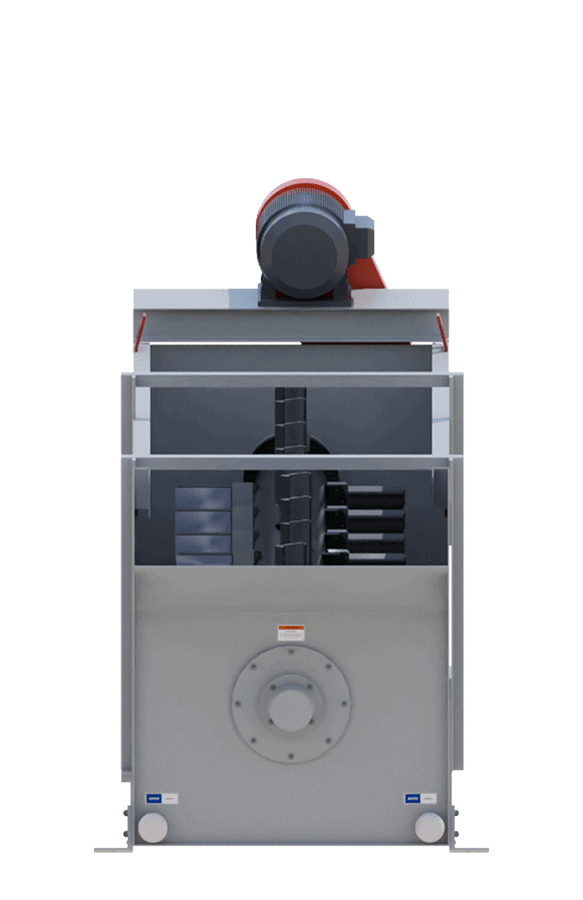

Blade Mill Washer

Improve Screening Efficiency

Often mounted on top of a screen tower, blade mill washers prepare feeds for further processing. A dry feed is converted to a wet slurry and then fed to a vibratory screen.

This improves screening efficiency as wet feeds go through a screen much faster than dry. Any water fed to a blade mill is water you don’t need to feed through your screen’s spray bars.

As the material processes up the blade mill tub, clays and crusher dust are washed from the rock. Include a set of overflow doors, and sticks and dirt will float out the side keeping this fugitive material from your screen.

- Capacities up to 720 STPH (650 MTPH)

- Operating Angle of 0° – 8°

- Tub lengths 24’ – 48’ (7.3 – 14.6m)

Models

BEARING OPTIONS

Safeguard™ Outboard Bearing

44×20 Single Screw shown

Standard design

Pillow block bearing

Bearing mounted away from tank

Retrofit kits for existing screws

Flange Mount Bearing

44×20 Single Screw shown

Uses flange block bearing

Matches footprint of EIW and Trio

Replacement parts available too

Downloads

Back to top »

Local Stock. Local Support. Local Experts!

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Blade Mill Washer

See our privacy policy.