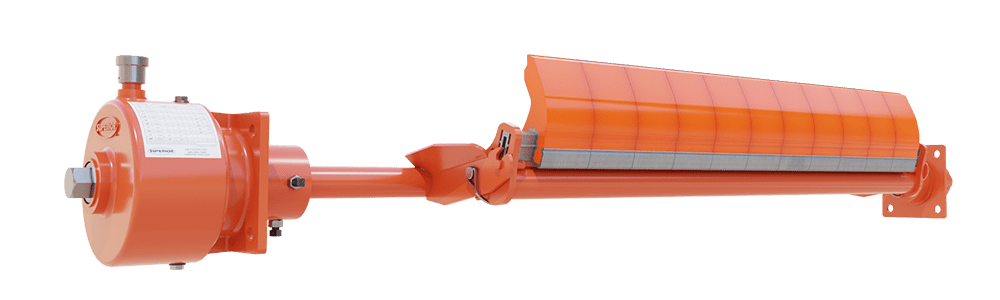

Exterra® Secondary

Belt Cleaner

Second to none

Unlike primary precleaners, Exterra Secondary Belt Cleaners accommodate greater levels of tension since the belt is clear of interference from the head pulley.

When a primary scraper leaves behind more carryback material than you can stand, consider installing a secondary cleaning system behind the drive pulley. Together, primary and secondary belt scrapers will remove at least 90% of all carryback material and usually much, much more.

- Belt widths 18” – 72” (457 – 1,828mm)

- Blade widths 15″ – 69″ (381 – 1,752mm)

- Pole lengths 48″ – 114″ (1,219 – 2,895mm)

Advantages

01.

Blade segments

Segmented blades individually conform to belting for best cleaning.

02.

tungsten tip

Baked into the apex of the blade is powerful tungsten carbide.

03.

Blade Angle

Adjustable blade angle accommodates both mechanical and vulcanized belt splices.

04.

Positioner Pin

Simplified design improves and speeds installation of blades.

New Option:

Adjust Tensioning More Quickly

- Adjustable dial sets tension according to belt width

- Cast aluminum cover protects springs from material

Downloads

Back to top »

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | exterra Secondary Belt Cleaner

See our privacy policy.