Washing Equipment

wash It

Generally, wet processing equipment removes unwanted material from feeds, aids in the formation of a spec, sizes and separates and/or removes moisture.

We wash sand and gravel for better roads and bridges, lasting foundations and — best of all — to command higher prices for our products.

scrubbing Equipment

Scrubbing removes minerals for a higher grade, higher value product.

CLASSIFYING Equipment

Using water, gravity and settling to separate then re-blend sand.

Washing Equipment

Using water to remove unwanted silt or clay.

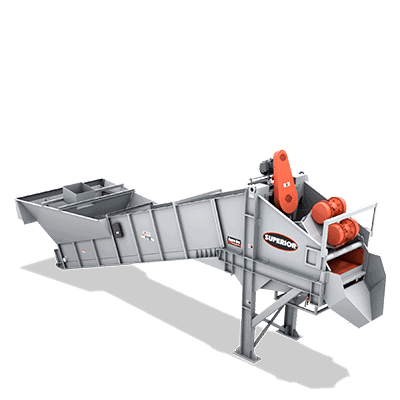

DEWATERING Equipment

Removing water in a product by mechanical means.

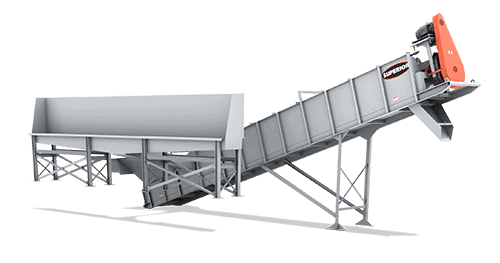

Concrete Washout System

Recover salable aggregate from ready mix trucks

Avoid wasteful disposal

Reduce washdown time and disposal site trips