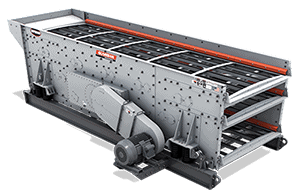

Guardian® Horizontal Screen

Maximize Your Rock Screening Efficiency

Superior’s vibratory horizontal screens are designed with satisfied owners in mind. That means every inch is consistently under investigation for improvement opportunities.

Repeatable quality is achieved during manufacturing thanks to work instructions at every stage, robotic assistance, and use of clean, shot-blasted steel to achieve higher quality welds and paint.

Our goal is best in class screening and that requires our constant attention!

Advantages

01.

Modern Spring Arrangement

Surge dampening calms start up and shut down, while bottle jack lifting points simplify maintenance.

02.

Moisture-Proof Manufacturing

Since so many screen machines go to wet applications, our sealing and anti-corrosion components are industry leading.

03.

Uniform Manufacturing

Work instructions at every stage, highest quality welding, robotic assistance, and inline assembly for consistent construction.

04.

Fabricated I-Beam

Creates the highest strength-to-weight ratio so you can put more rock shaking action into your screens.

How Does A Horizontal Screen Work?

Horizontal screens operate at a relatively flat angle usually less than 10°. A series of shafts produce a vibrating effect, which moves the material down the length of the screen.

Larger material stays on the top deck while smaller rocks and stones fall through up to four layers of uniquely sized screen media. The result is segregation by screen opening size.

Horizontal vs Inclined Screens

Horizontal Screen

Uses oval throw to move material

Most accurate particle sizing

Accommodates heavier bed depths

Low height is great for portability

More complex drive system

Inclined Screen

Uses gravity to move material

Typically lower capital expenditure

Processes higher capacities

Usually mounted in stationary plants

Simple design, easy to operate

SEE ANTHEM® INCLINED SCREENS »

Local Stock. Local Support. Local Experts!

Videos

Walk around the screen with us to see our most unique features.

Tour our rock screening manufacturing plant to see what best in class means.

Back to top »

We put more horizontal shakers into wet applications than anyone else.

models

Have questions? Need a quote? Complete the form below and we will follow up shortly.

REQUEST MORE INFO | GUARDIAN HORIZONTAL SCREEN

See our privacy policy.