Impact Bed

cushion the blow

Did you ever participate in the egg drop experiment during science class? (Your goal was to create the most protective packaging so the brittle egg inside was cushioned during the drop.) That simple experiment is similar to the concept of an impact bed.

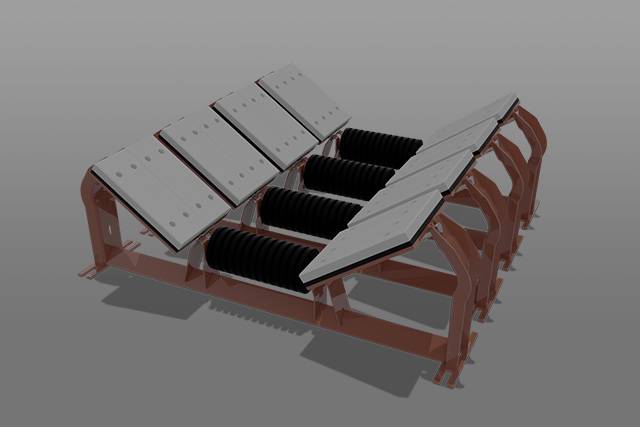

Constructed with energy-absorbing materials, the impact bed is designed to protect conveyor belting from the beating of falling material within the load zone.

Actually, the material doesn’t always need to be big and lumpy. Sometimes, impact beds are used to soften the blow of material from extended distances as it free falls from discharge chute to hopper target.

- Belt widths 24” or 72” (609 – 1,828mm)

- Lengths 4′ – 5′ (1.2m or 1.5m)

- Standard Duty: up to 200 lbs/ft (91kg)

Advantages

01.

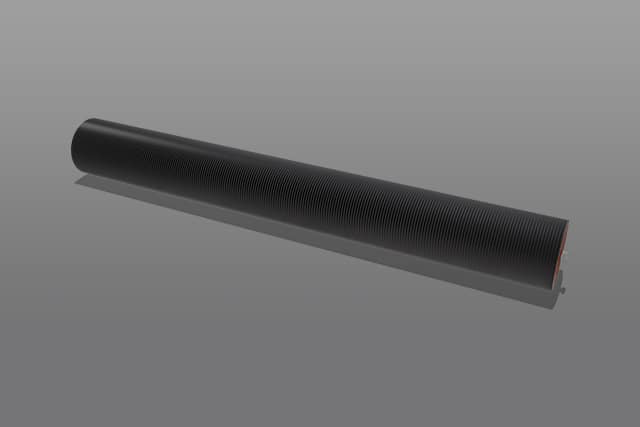

impact bars

Top layer of low friction UHMW and bottom layer of high impact SBR rubber.

02.

Adjustable wings

Wings adjust to 20°, 35° and 45° to contain material transferred to load zone.

03.

Structural frame

Rigid, structurally sound frame provides extra support.

04.

Expedited Deliveries

Local distribution, elite welders, and in-house testing all contribute to expedited components deliveries.

impact bed

vARIATIONS

Standard Duty

Up to 200 lbs/ft (91kg)

Medium Duty

Up to 960 lbs/ft (435kg)

ENGINEERED CLASS

Designed to Application

Back to top »

Downloads

Back to top »

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Impact Bed

See our privacy policy.